Print consistency rarely comes down to one dramatic variable. In most cases, it’s the accumulation of smaller, easily overlooked details that determines whether a job repeats cleanly week after week. That’s where working with a specialized photopolymer sheet manufacturer matters. At PlateCrafters, we’ve spent decades understanding how material integrity, plate construction, and prepress discipline influence what happens on press. When the goal is reliability, experience becomes its own form of insurance.

Craftsmanship Anchored in Real Production

PlateCrafters didn’t stumble into this work by accident. Our entire shop is built around the craft of making photopolymer plates. We’ve refined a process that respects traditional plate-making but pairs it with current digital systems, because neither approach, on its own, covers every situation. That balance is why we excel as one of the most dependable photopolymer plates suppliers in the field.

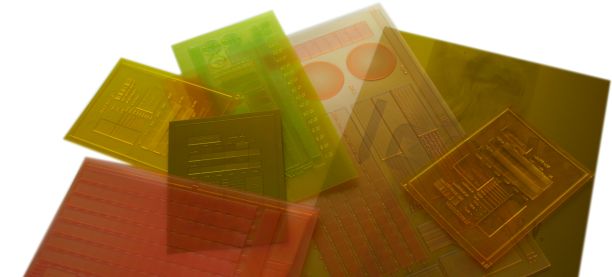

Being a focused photopolymer sheet manufacturer forces us to obsess over the nuances that non-specialists ignore- exposure curves, relief depth, shoulder profiles, surface consistency, plate gauge selection, and predictable behavior on press. When you’re printing packaging, labels, corrugated, or pharmaceutical work, those details are what hold everything together.

Material Choice Is the First Fork in the Road

You can’t separate plate performance from plate material. We produce both digital and analog photopolymer plates because different presses, workflows, and product types react differently to each format. Digital plates give cleaner walls and higher detail retention. Analog plates provide durability and cost efficiency for certain applications.

Our responsibility, as a specialist, is to guide customers toward the exact material they need, not the material that happens to be in stock. We stock multiple gauges and plate sizes up to 50×80 inches, which lets us align equipment constraints with production realities. When a printer trusts a generalized vendor, it rarely gets that level of precision. And precision is what consistency feeds on.

Consistency Begins Long Before the Press Starts Rolling

There’s a misconception that consistency is something achieved on the press floor. In truth, most consistency is created before a job ever reaches a cylinder. A dedicated photopolymer sheet manufacturer controls the prepress path with the same intent that a good operator applies to their machine.

At PlateCrafters, each file is reviewed by highly trained artists who know the difference between a passable separation and one that actually prints clean. Our prepress team handles trapping, alignment, optimization, and practical problem-solving with the press in mind, not simply the screen. That’s the kind of quiet work that minimizes variables later.

When customers choose us as their photopolymer plates suppliers, they’re not only buying a plate, they’re investing in a process designed to anticipate trouble before it can waste material.

Also read: Expert Engraving for Sand Casting & Flexographic Plates.

Every press has its quirks. It’s the nature of mechanical systems. Some drift as rollers warm up, some shift as blankets age, some change tone balance depending on humidity or stock.

We don’t ignore those tendencies; we study them. Our fingerprinting process allows us to track how a press behaves through live production jobs. Instead of theory, we measure reality. And we adjust plate construction based on that reality. We want your second run, and your tenth, to feel just as clean as the first.

This is the advantage of working with a specialized photopolymer sheet manufacturer rather than a surface-level vendor- we understand that consistency must be engineered, not hoped for.

Speed Without Sacrificing Quality

Fast and consistent aren’t mutually exclusive. We produce plates quickly because our workflow is tight, not rushed. The goal is always the same- correct plates, the first time. Same-day turnaround is standard here because print schedules rarely forgive hesitation.

That speed only matters if the plates hold up on press. They do. Our quality control is disciplined, not ceremonial. It’s based on craftsmanship and accountability.

Designed to Reduce Waste

A printer paying for waste is a printer losing margin.

When your plates behave the same every run, you cut-

- setup time

- color chasing

- unnecessary impressions

- stock loss

- stop-and-start frustration

Good plates stabilize the floor. Exceptional plates stabilize your business.

That’s why working with a dedicated photopolymer sheet manufacturer matters more than it may appear. It’s not about a single job, it’s about every job afterward.We specialize in providing modern flexo plate solutions, and Digital Photopolymer is at the center of this innovation.

Final Thoughts

Experienced printers eventually realize the same truth- consistency beats brilliance. Consistency is what keeps the customer coming back. And consistency is exactly what PlateCrafters is built to provide.

As one of the most trusted photopolymer plates suppliers, we bring specialized material knowledge, disciplined production, dedicated prepress support, and a commitment to doing things correctly, not quickly, not cheaply, but correctly.

If you want stable, reliable output across repeated runs, start with the part of the process that shapes everything else- the plate.