Among the many metals used in the printing and stamping industry, magnesium plates hold a special place. Lightweight yet durable, magnesium is easy to etch and can be processed quickly, which makes it a popular choice for a wide range of applications. From magnesium foil stamping dies to embossing, debossing, engraving, and letterpress, this material has proven itself to be both versatile and cost effective.

Understanding Corrugated Printing Plates

Magnesium is one of the lightest metals available, yet it etches cleanly and with great precision when processed with nitric acid. This ability to create sharp, raised images makes it suitable for more than 90 percent of die-making jobs. While heavier metals like copper and brass still serve important roles in certain high-end or extremely detailed work, magnesium has become the go-to choice for most applications.

Read Also: Why Magnesium Foil is a Great Choice for Hot and Cold Foil Stamping.

Advancements in both the raw material and the etching process have pushed magnesium’s quality to levels that rival those heavier metals. For printers and manufacturers, this means they can rely on magnesium not only for affordability and speed but also for the fine detail required in today’s packaging and finishing work.

The Plate-Making Process

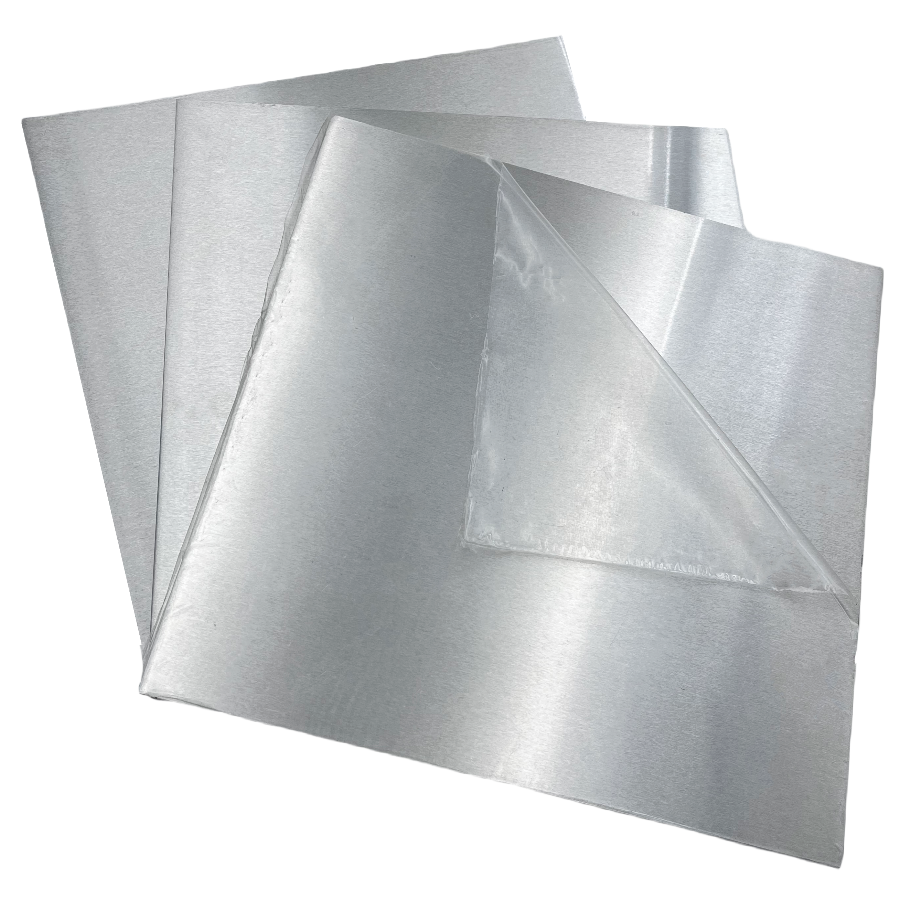

Raw magnesium arrives in sheet form, each coated with a light-sensitive resist layer. When exposed to light, this coating hardens and resists acid. The plate is then developed and placed in a nitric bath. The acid removes the unprotected areas of magnesium, leaving behind the raised image that will transfer foil or create impressions during embossing or printing.

After etching, the plates are cleaned, trimmed, and prepared for use. Embossing dies often require molded counters to ensure a perfect fit, while letterpress cuts can be mounted to reach type-high. The entire process is remarkably efficient, often completed in less than an hour, which allows many magnesium jobs to be turned around the same day.

Precision and Craftsmanship

While technology has streamlined the process, making magnesium foil stamping dies is still very much an art. The acid bath must be carefully balanced, and experienced craftsmen monitor each stage to maintain quality and consistency. Small details in handling and timing can make a big difference in the clarity and durability of the final die.

At PlateCrafters, multiple magnesium production lines are supported by a team of skilled plate makers who have decades of experience. This combination of technology and human expertise ensures every die meets the highest standard. The company has supplied magnesium dies to some of the world’s largest printers, proving that magnesium remains a trusted choice for everything from commercial packaging to specialized print projects.

Why Magnesium Remains the Go-To Choicep

Speed, affordability, and quality are what make magnesium plates so widely used in foil stamping and finishing. They allow printers to meet deadlines without compromising detail. They also offer the flexibility to serve many different applications, from awards and plaques to high-volume packaging runs. And while copper may still be required for certain intricate or long-life jobs, magnesium provides the right solution for most projects.

For businesses looking to balance performance with efficiency, magnesium foil stamping dies continue to be the smart option. PlateCrafters remains committed to delivering reliable magnesium solutions backed by experience, craftsmanship, and service.