In flexo printing, everyone talks about ink, press speed, and substrates. But none of those matters if the plate isn’t right. Your photopolymer plate isn’t just a tool; it’s the foundation. If that foundation is off, your press won’t save you. Ink won’t fix it. And your final product? It’s going to show every flaw.

The truth is, too many shops still accept average plate performance as the ceiling. It’s not.

At PlateCrafters, we work from the plate backward. Because everything downstream, sharp halftones, ink transfer, and durability, depends on how well that plate was made, and who made it.

We’re not a side-hustle operation. We’re a photopolymer sheet manufacturer focused solely on getting this one thing exactly right.

Materials First. Always.

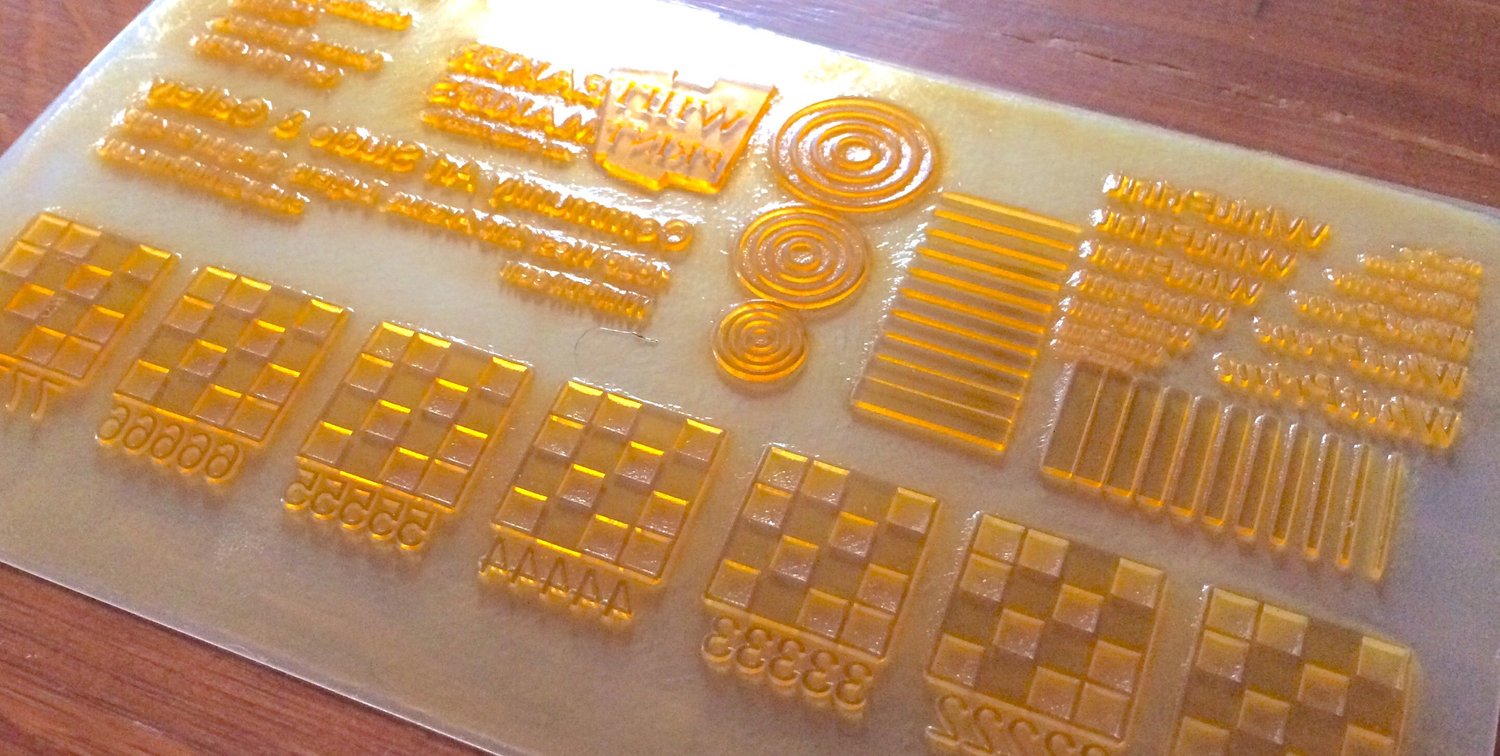

Photopolymer is a chemically engineered plastic that hardens under UV light. Everyone in this industry knows that. But what they don’t always realize is how much the formulation has evolved.

Today’s high-end photopolymers can hold tighter screens, resist collapse under pressure, and lay ink cleaner across variable substrates. But you only get that performance if your supplier is using the newest generation of sheets, not just what’s cheapest or easiest to process.

We use only the highest-grade materials available. No compromises, no mystery stock. If a new sheet formula outperforms what we’re using, we switch. Not because it’s trendy, but because we test everything on press before we send it to you. If it doesn’t hold up, it doesn’t leave the shop.

Technology Is Useless Without Context

Lasers get more precise every year. Exposure units, washout systems, processing software, it’s all getting smarter. But without the judgment of someone who’s actually seen bad plates hit good presses, it doesn’t matter.

We don’t just process files. We build plates that are tuned to the real conditions they’ll be used in. Different ink systems. Different impression settings. Thermal vs. solvent. Short vs. long runs. Coated vs. uncoated stocks. These details matter. A lot.

We’re obsessive about nuance because photopolymer printing plates is unforgiving. It exposes carelessness. If your shoulder angles are wrong, if your relief depth is inconsistent, if your screens aren’t hitting the substrate correctly, your print won’t lie for you.

And when your customer holds that finished package in their hand, they won’t care if it was a plate issue or an ink problem. They’ll just know it looks off.

Why Most Shops Shouldn’t Make Plates In-House

Look, we get it. On paper, doing your own plates seems like a smart move. More control. Lower costs. Faster turnaround.

In reality, unless you’re willing to keep investing in updated equipment, software, and materials, what you’re really doing is limiting the quality your press is capable of delivering.

Flexo has evolved. Clients expect tighter tolerances, higher resolution, and cleaner results. If your plates aren’t on par, you’re stuck trying to fix issues mid-run, tweaking pressure, chasing registration, and over-inking.

We work with printers who want to avoid that headache entirely. They send us files; we send them photopolymer plates that just… work. Every time.

That’s what a good photopolymer sheet manufacturer should do: make the problem disappear before it shows up on the press.

Also Read: Dry Offset Plate Printing Solutions – PlateCrafters Experts

Precision at the Start Saves You Everywhere Else

Bad plates cost more than just money. They waste time, exhaust operators, and erode trust. They turn tight schedules into blown deadlines. But a good plate? It shortens your setup. It prints cleaner. It runs longer.

That’s the real ROI.

PlateCrafters doesn’t sell dreams. We sell consistency. We’ve been at this long enough to know what works, and more importantly, what doesn’t.

If you need analog, digital, thermal, solvent, flat-top, high-durometer, or custom thickness, we do it. Not because we’re trying to be everything to everyone, but because photopolymer isn’t one-size-fits-all. You need the right material for your job. And someone who knows how to use it.

Call us when the quality of your print matters. We’ll handle the plate.