If you’ve ever tried printing on corrugated boxes with standard flexo plates, you already know the outcome. Uneven impressions. Lost detail. Waste. That’s not a design issue, it’s a plate problem. Flexo printing on corrugated substrates needs the right materials, the right softness, and the right mount. Otherwise, your output suffers.

That’s why corrugated printing plates from PlateCrafters aren’t just another option. They’re built specifically to handle the peaks and valleys of corrugation without crushing detail or compromising alignment. We don’t offer liquid polymer because we know it doesn’t hold up. Inconsistency isn’t something we accept.

Built for Corrugated, Not Adapted to It

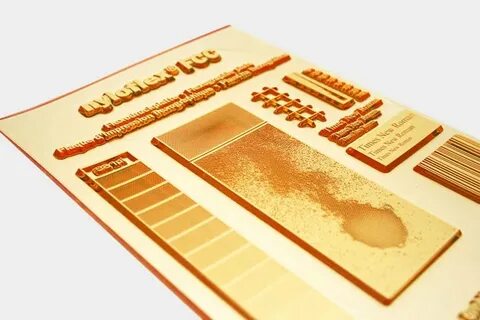

Flexo printing on Corrugated Flexographic Printing Platesstock works differently. You’re not printing on smooth, flat material. You’re working with ridges, grooves, and a surface that pushes back. That’s why our sheet photopolymer plates are made soft enough to absorb that structure, yet firm enough to hold a clean impression.

You can get them loose at .250 thickness if you prefer to mount in-house. Or we can deliver them fully mounted, color-aligned, and press-ready. Our Harley mounters give us full control over precision, so your final prints stay sharp across every panel of the box.

Why PlateCrafters Plates Actually Perform

Let’s make this clear. We only manufacture sheet flexo plates because we care about consistency. Liquid polymer options might save you money in the short term, but they won’t give you the repeatability or performance your team needs. One run might work. The next one fails. That’s not how we do business.

Our quality guarantee and price match program speak for themselves. If you’re stuck with plates that crack, misalign, or fade under pressure, we’ll fix that. Give us the specs. We’ll match them. No extra jargon, no empty promises.

Not Just Boxes, Any Industry That Prints with Flexo

Corrugated is only one part of what we do. Our plates are also used in:

- Labels and tags

- Bags, rollstock, and banners

- Pharmaceutical blister packs

- Barcodes and security printing

- Leather embossing

- Greeting cards and business forms

- And dozens of other specialty applications

We’ve been in this since 1971. And our first customer is still with us. That doesn’t happen without real trust and reliable results.

Also Read: How Custom Foil Stamps Elevate Your Print Projects

A Company That’s Evolved Without Losing Its Edge

Our story started with rubber plates. Then came photopolymer. Then digital. Now we use the most advanced screening and resolution tools in the industry, but we haven’t lost what got us here: pride in the details and commitment to doing the job right.

With locations in the Northeast, Southeast, and Midwest, we’ve expanded without dropping quality. If you’ve outgrown your current plate vendor or are scaling up production, we’re built to keep up.

Ready to Switch? Let’s Talk Plates

Here’s the thing. Not all Corrugated Plates are the same. And not all vendors care if your print job actually runs the way it should. We do. That’s why we only use materials that work, and why our mounting process is so precise. Whether you’re running basic shipping cartons or full-color display boxes, we’re ready to build plates that match your expectations and your press.

Shop Corrugated Plates from PlateCrafters today and print like it matters.